Supervisor or Top Man

Supervisors should be given the responsibility to ensure that the necessary precautions are taken, to check safety at each stage and to remain in attendance whilst work is being undertaken, if necessary.

Duties include:

- Check entrants and their PPE (Correctly fitted, inspection in date, suitable).

- Check entrants competency levels (Skills, knowledge and experience).

- Training received must be appropriate to task.

- Keep unauthorised persons away.

- Brief team prior to entry (Task in hand, safety requirements, emergency arrangements).

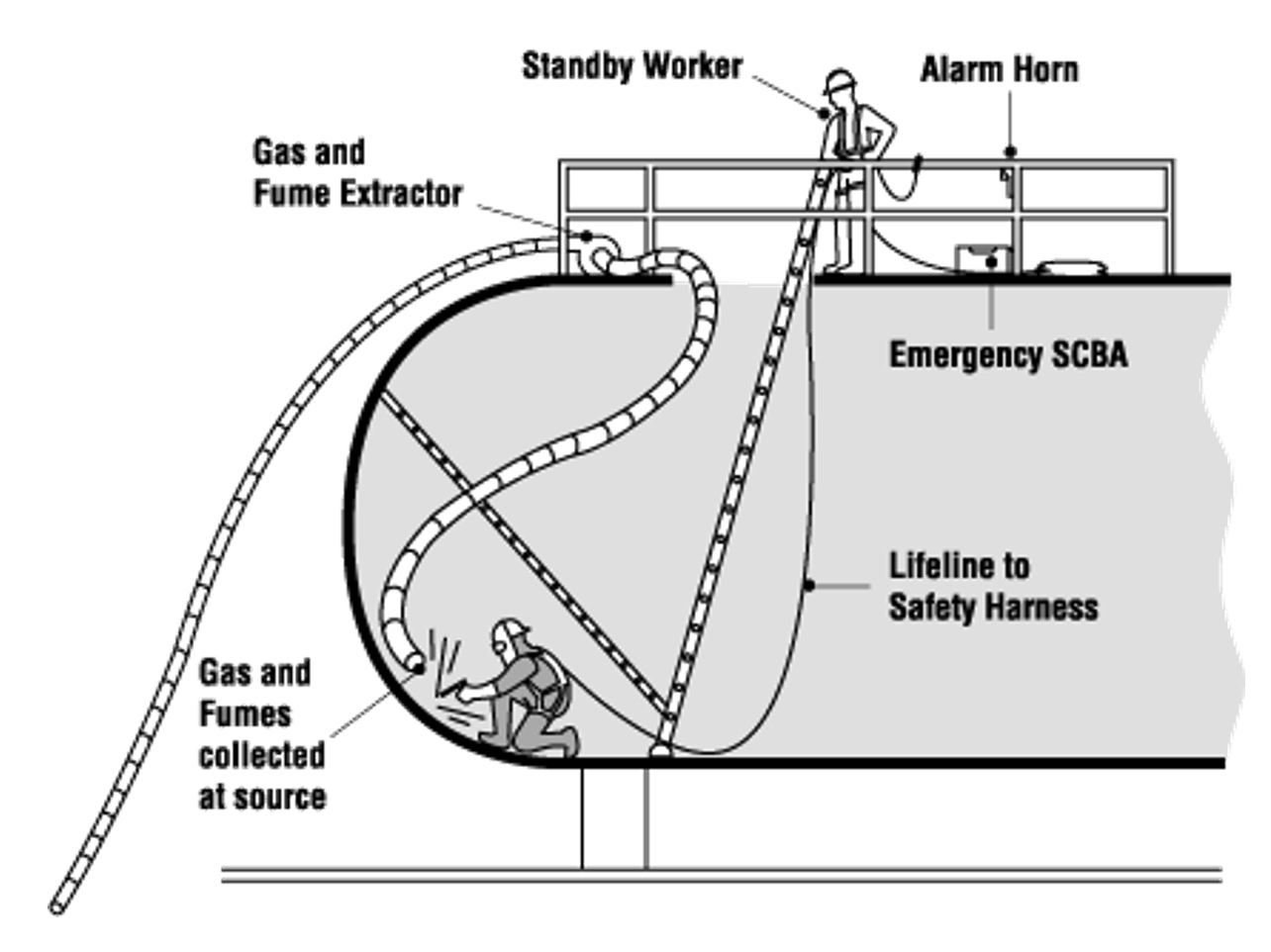

- Maintain communications, e.g. radios or line (rope) for example.

- Communications between those inside the confined space.

- Between those inside and outside.

- To summon help in case of an emergency.

- Be aware of any changing conditions.

- Look and listen for problems with entrants.

- Raise the alarm.

- Record entrant or teams location(s), plant/equipment taken within the confined space.

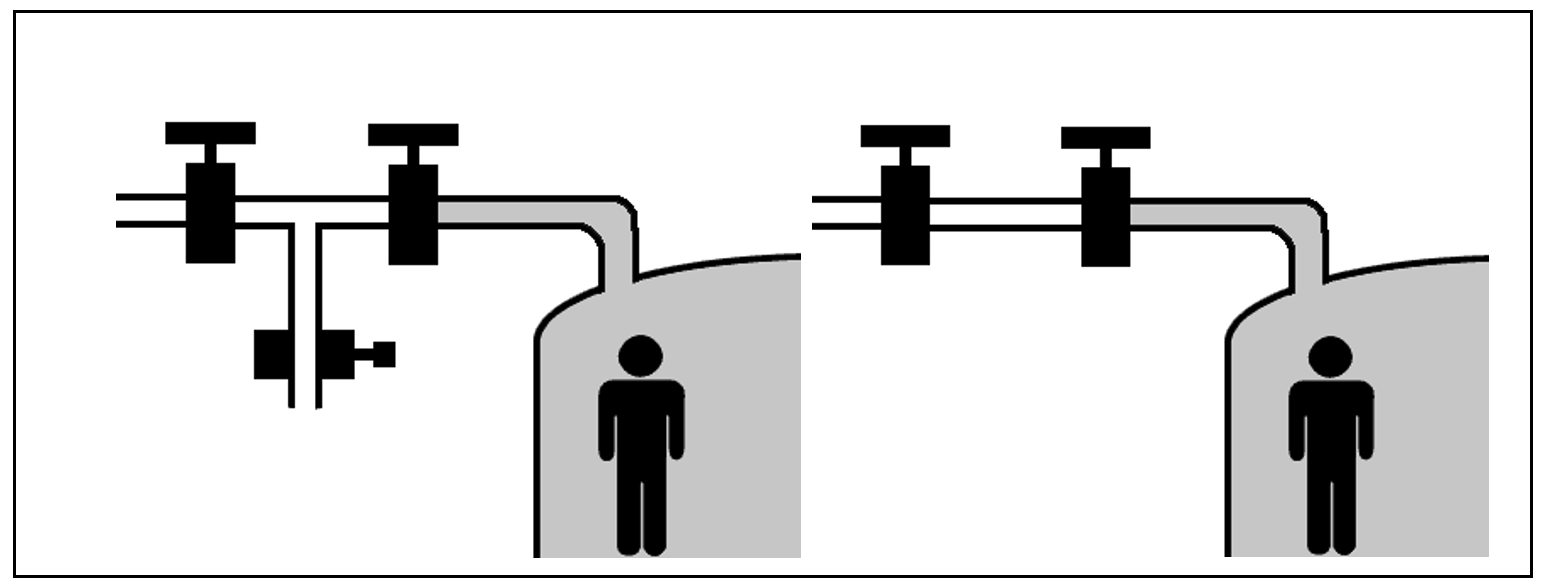

Isolation – Mechanical and electrical isolation of equipment, processes etc. is essential if it could operate inadvertently either by remote means or physically. All isolations must be sufficient and effective. These may include lock off or lock out tags, which must correspond with the permit to work. All isolations must be carried out by a competent person.

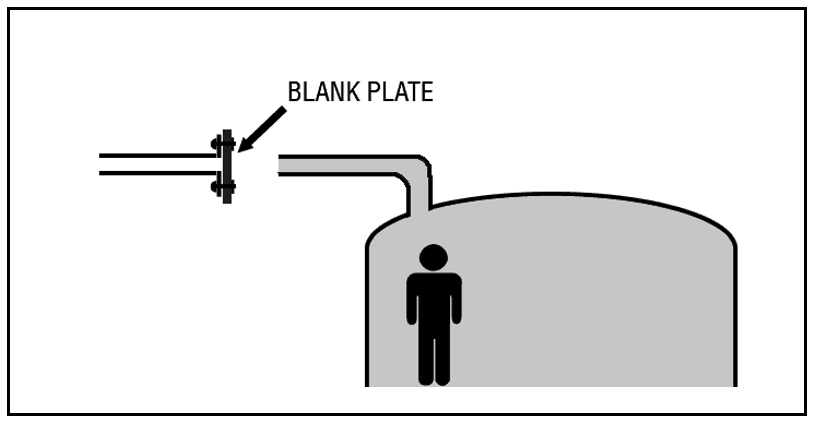

Isolation from the ingress of substances such as gases, fumes, liquids and other flowing materials must be considered and actioned within the permit to work. An effective method is to simply disconnect or remove pipework or ducting or inserting blanks. When using blanks, there must be no possibility of there removal without authorisation therefore suitable locking procedures are required. Proximity

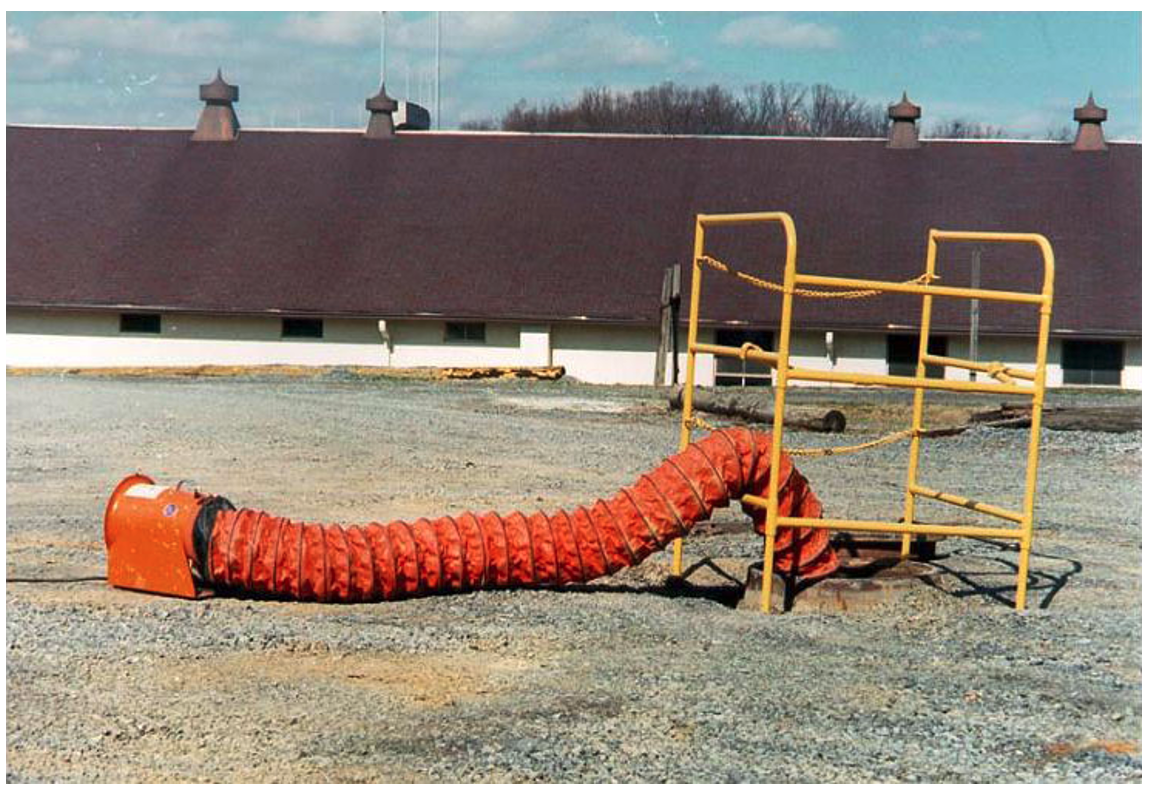

Provisions for ventilation – Some confined spaces are enclosed by virtue of their design and therefore require mechanical ventilation to provide sufficient breathable air being used up by the occupants or to dilute or remove gases, fumes, vaours etc. from the process. This can be done using blower fans, trunking or an exhaust fan or ejector and trunking.

Never introduce additional oxygen into a confined space to ‘sweeten’ the air as this can lead to an oxygen enriched atmosphere that can render certain substances to spontaneously combust, e.g. grease.

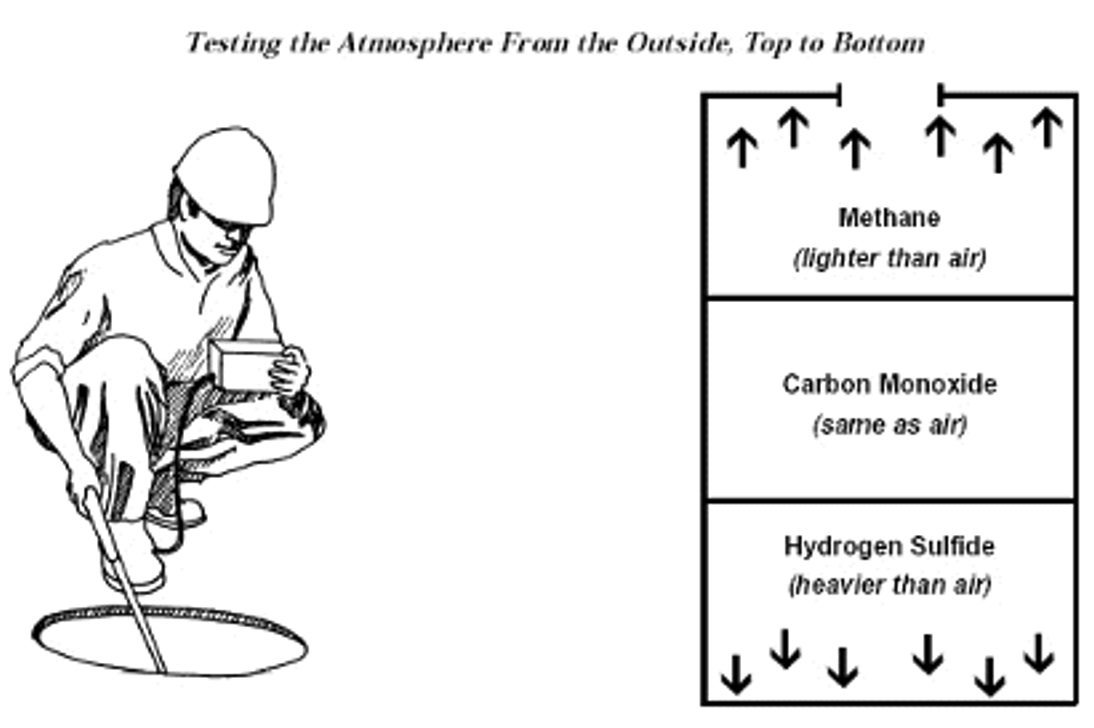

Testing and monitoring the atmosphere – The atmosphere within a confined space should be tested for hazardous gases, fumes, vapours, or to check the oxygen concentration prior to entry. Testing should be carried out when there’s knowledge of its previous contents or if chemicals used in any prior activity within the space may indicate the atmosphere would be unsafe to breathe. Testing should be done by a competent person, and be conducted at least 5 minutes prior to entry. Testing can be carried out initially from outside, without the need for entry, drawing sample results through a long probe or just lowering down the monitor on a line.

Purging – Where the risk assessment indicated the presence or possible presence of flammable or toxic gases or vapours there may need to purge the gas or vapour from the confined space. This can be done with air or an inert gas where toxic contaminants are present, but only use an inert gas on flammable gases or vapours as using air may produce a flammable mixture.

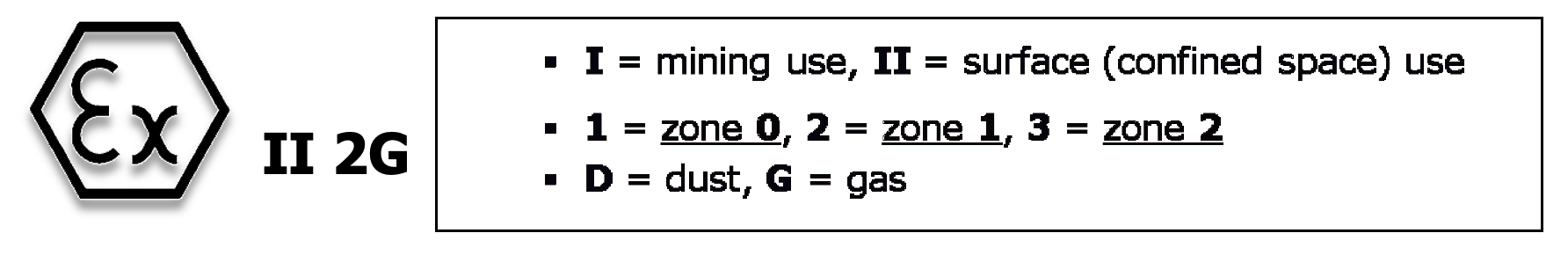

Equipment – Any equipment used must be suitable and fit for purpose within a confined space. Particularly where there’s a risk of a flammable gas presence, which could be ignited by an ignition source, e.g. hand held portable lighting, specially protected electrical equipment needs to be used which is intrinsically safe.

Dangerous Substances, Explosive Atmosphere Regulations DSEAR) 2002 defines hazardous areas according to the probability of their being an explosive mixture present.

Reference: BSEN 60079/10

- Zone 0 – An explosive mixture is continuously present or present for long periods

- Zone 1 – An explosive mixture is likely to occur in normal operations

- Zone 2 – An explosive mixture is not likely to occur in normal operations and if it does will only be for short periods.

Intrinsically safe gas detectors may have two (i) rating;

- ia – Less likely to igniter an explosive atmosphere under fault conditions and used be used in Zones 0, 1 and 2.

- ib – Should not be used in Zone 0 but is suitable for Zones 1 and 2.

Additional markings meaning:

- EX – Mark of certification authority

- E – Approved to European norm (ATEX)

- T 4 – Temperature class (T4 suitable for gases and vapours with ignition temperatures more than 135ºC)

Smoking – THIS IS PROHIBITED WITHIN CONFINED SPACE. This includes the carrying of matches etc. If smoking is to be allowed on site, then an exclusion zone of 5-10 metres needs to be established.

Emergency and Rescue – Under the Confined Space Regulation 1997, regulation 5 and page 5 on this document they need to be suitable and sufficient and where appropriate, there will also be a need for the necessary equipment to enable resuscitation procedures to be carried out. These arrangements should be in place prior to entry by any person.